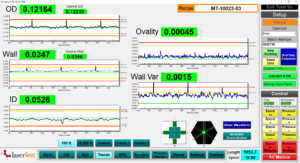

PROCESS VISUALIZATION

BEYOND MEASUREMENT

A PARTNERSHIP

FOR SUCCESS

Using laser and ultrasonic-based technologies, LaserLinc helps you solve your in-process and off-line non-contact measurement and visualization needs through product innovation, software expertise, and deep application knowledge. LaserLinc offers you the most dependable non-contact measurement solutions available. Our professional team of experts makes it easy for you to implement a range of robust and flexible solutions to enhance your production environment and improve your yield.

Using laser and ultrasonic-based technologies, LaserLinc helps you solve your in-process and off-line non-contact measurement and visualization needs through product innovation, software expertise, and deep application knowledge. LaserLinc offers you the most dependable non-contact measurement solutions available. Our professional team of experts makes it easy for you to implement a range of robust and flexible solutions to enhance your production environment and improve your yield.

STRATEGIC PARTNERSHIP.

CUSTOMER SUCCESS.

Microspec extrudes advanced medical tubing including small and complex tubing with the tightest tolerances. Tim Steele, Microspec Founder/CEO discusses their success and partnership with LaserLinc.

Learn how our laser micrometers, ultrasonic wall measurement solutions, and visualization software help solve difficult challenges here.

STRATEGIC PARTNERSHIP.

CUSTOMER SUCCESS.

Microspec extrudes advanced medical tubing including small and complex tubing with the tightest tolerances. Tim Steele, Microspec Founder/CEO discusses their success and partnership with LaserLinc.

Learn more about our comprehensive line of in-process and off-line products for measuring wall thickness, inner and outer diameter here.

THE PRECISION YOU NEED.

THE PARTNERSHIP BEYOND MEASURE.

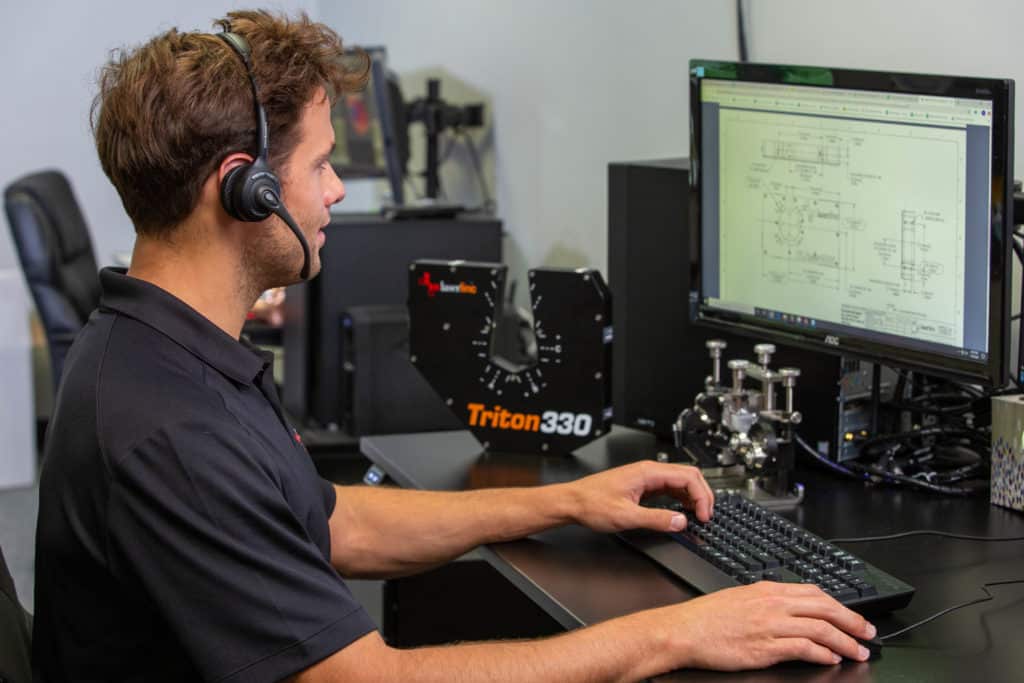

When you need a measurement partner with deep industry expertise, the LaserLinc team is ready with the world’s most dependable solutions. You’ll get a partner who listens first, ensuring you get a configuration that fits your needs and can grow with your operation. You’ll also benefit from the unmatched application knowledge of people who understand your business, world class customer service, and the industry’s only open architecture.

THE BEST WARRANTY

IN THE INDUSTRY,

PLUS WORLD-CLASS PERSONAL SUPPORT

You’ve got more options with LaserLinc

Every minute of downtime hits your productivity and profits. Our unique policy of always providing personal contact with our service support team ensures you will get back online quickly. You’ll get expert advice from application engineers who understand your business challenges, plus on-site service if necessary.

All LaserLinc manufactured products are backed by an industry-leading four-year warranty. LaserLinc is a U.S. company and proud to design and manufacture its products at its headquarters in Fairborn, Ohio.

EXPERT ADVICE

LaserLinc understands how critical your in-process and off-line measurements are, for outside diameter, ovality, wall thickness, concentricity, eccentricity, profile and more. We support a full range of in-process and off-line non-contact and sample measurement solutions for medical, wire & cable, automotive, industrial, monofilament, and other industries. Have a question about one of our products? Looking for expert advice on how to solve a unique measurement challenge or need technical support? We’re here to help.